basalt Rebar and rebar mesh

Basalt Rebar and Rebar Mesh are high-performance reinforcement materials made from basalt fibers, providing a sustainable and superior alternative to traditional steel reinforcement in concrete. Both are lightweight, strong, non-corrosive, and recyclable, offering multiple advantages over conventional steel.

While Basalt Rebar is produced in long, continuous rods, Basalt Rebar Mesh is available in large rolls designed for reinforcing larger surface areas. These two forms together provide versatile solutions for a range of concrete reinforcement needs.

Key benefits of basalt rebar

-

Basalt rebar has a tensile strength 3 times greater than steel, providing superior reinforcement capabilities while being resistant to corrosion, rot, and temperature extremes.

-

Basalt rebar is 4 times lighter than steel, simplifying transport, installation, and reducing labour costs.

-

Unlike steel, basalt is resistant to corrosion, allowing for reduced concrete cover thickness—just 10 mm compared to the 40 mm needed for steel—saving on materials and labour.

-

The use of basalt reinforcement reduces both material waste and costs during construction, providing a significant cost-saving advantage.

-

Basalt rebar and mesh do not conduct electricity, making them suitable for environments where electrical safety is critical.

-

All basalt products are recyclable at the end of their lifecycle, supporting sustainable construction practices.

Basalt rebar

vs

basalt rebar mesh

-

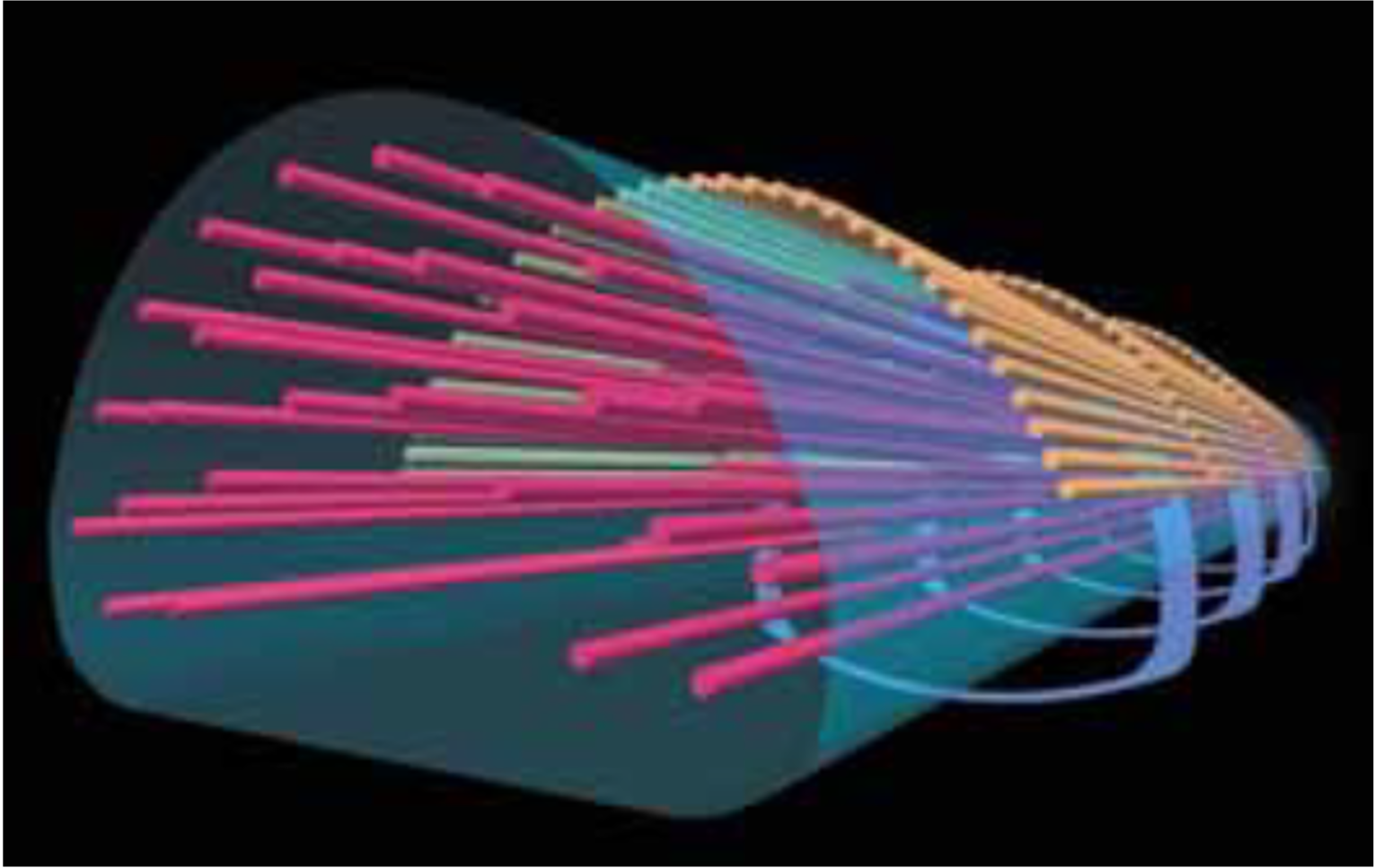

Basalt rebar

Basalt rebar is used as a direct alternative to traditional steel rebar for concrete reinforcement.

Its high tensile strength, combined with its corrosion resistance, makes it ideal for structural applications where longevity and reduced maintenance are crucial.

Available in:

Diameters ranging from 4mm to 16mm and in various lengths up to 800m, basalt rebar can be easily rolled for transportation, reducing logistics costs and simplifying handling.

-

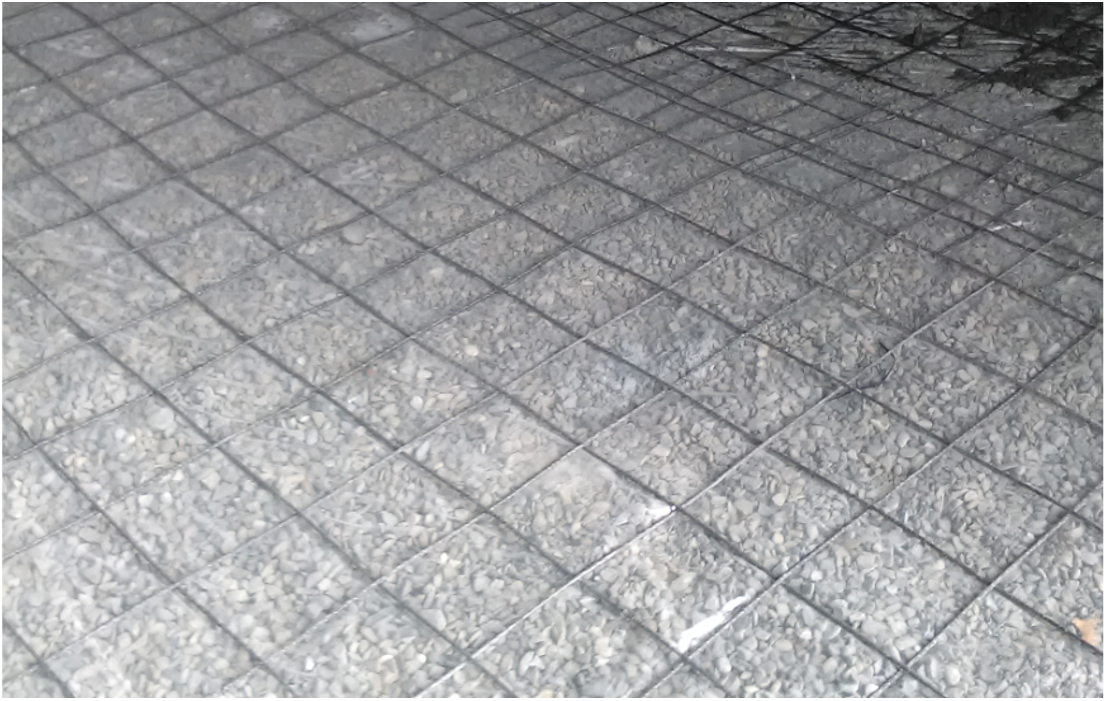

Basalt Rebar Mesh

Basalt Rebar Mesh offers reinforcement for larger surface areas, such as concrete flooring, pavements, and walls.

Basalt Rebar Mesh provides efficient reinforcement, reducing the thickness of concrete layers and saving costs on materials.

Available in:

Roll sizes of 2m x 50m, basalt mesh is lightweight (only 27kg for 100m²) and easy to install, with reduced installation times compared to traditional steel mesh.

Mesh sizes range from 50 × 50mm to 150 × 150mm, coated or uncoated, depending on the application.

Applications of rebar

Basalt rebar and mesh are widely used in construction and infrastructure projects, including flooring, road construction, and foundation reinforcement. They offer key advantages such as cost efficiency, corrosion resistance, and enhanced load-bearing capacity, making them ideal for industrial, commercial, and infrastructural applications.

| Concrete Construction |

| Road Construction |

| Commercial Development |

| Foundation Reinforcement |

| Infrastructure |

| Concrete Construction | | Road Construction | | Commercial Development | | Foundation Reinforcement | | Infrastructure |

Learn more about rebar and mesh

International Regulations, Performance, and Standards Compliance

International Standards: Complies with the following standards for plastic reinforced rebar:

CAN/CSA-S6-06 (1996), CAN/CSA-S806-02 (Canada)

440.1R-06, 440.2R-08, 440.3R-04 (USA)

CNR-DT 203/2006 (Italy)

JG/T 406-2013, JT/T 776.4-2010 (China)

ДСТУ-Н Б В.2.6-ХХХХ:2011 (CIS)

Load Capacity: Basalt rebar has a tensile strength of 1700 MPa, which is significantly stronger than traditional steel.

Thermal Performance: Linear thermal elongation coefficient of 8 ppm/°C ensures stability under thermal changes.

Corrosion Resistance: Demonstrated high resistance to corrosion, providing better longevity compared to steel rebar.